Home » Technical Resources » Case Studies » Caster Case Studies » Helping Aircraft Fly Through Maintenance

Working on an aircraft tail assembly is a tall order. With many standing over 30 feet tall, it’s a hard area to inspect or repair. Many maintenance facilities erect scaffolding or use aerial lifts to reach the tail assembly of commercial jetliners. With the time and effort involved in erecting scaffolding or the expense and hassle of using aerial lifts, it’s hard to keep up with today’s cost-conscious airlines with these tools.

Tri-Arc’s Custom Solutions – a Pittsburgh, PA-based company that manufactures rolling ladders and access equipment has designed an aircraft maintenance platform to completely enclose the tail assembly. Seeing a need to make it easier and safer to maintain the approximately 18,000 passenger and cargo jets in service today, Tri-Arc developed a massive, three-level structure that provides a safe, stable work area. Realizing the need to move this structure easily, Tri-Arc contacted the engineers at Conveyer & Caster-Equipment for Industry.

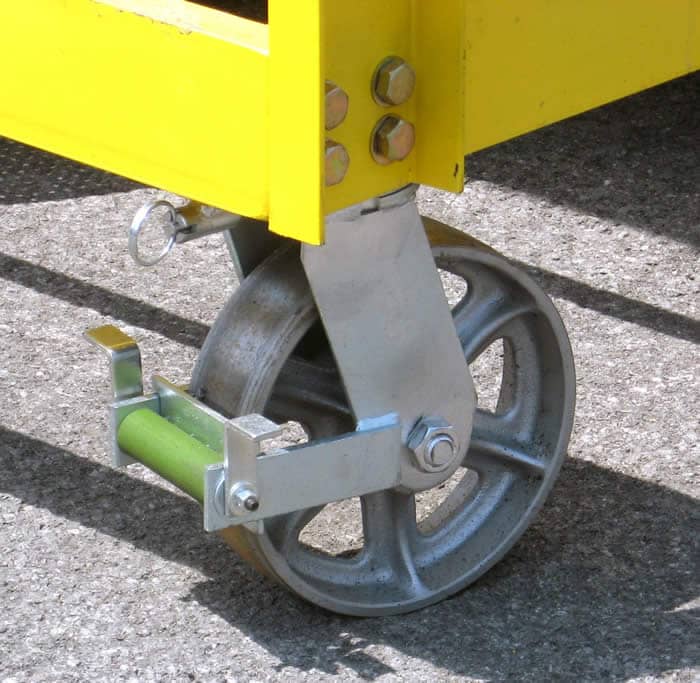

After reviewing the weight of the unit, similar to a three-floor building, Conveyer & Caster – Equipment for Industry recommended and provided 12” diameter steel wheels in an extra heavy duty rig assembly. A poly-type braking system and swivel lock were also designed to keep the wheels from rolling when the platform is in use and manned by aircraft mechanics.

Heavy duty floor jacks are also installed on the platform to help lock the platform in place. Conveyer & Caster – Equipment for Industry provided the leveling jacks as well as the rubber bumpers attached to the side of the platform that could come in contact with the aircraft’s fuselage. The bumpers are cut to length and drilled to easily install on the platform. As an option, Tri-Arc has designed a platform capable of lifting and removing an entire tail assembly from the aircraft. Conveyer & Caster – Equipment for Industry engineers worked closely with Tri-Arc to design and provide a floor mounted jib crane and hoist to access and remove a tail assembly. The motorized jib crane rotates the tail assembly away from the aircraft and the hoist allows for accurate up and down movement when lowering the assembly to the floor below.

Trying to inspect, maintain and repair an aircraft all within a 7-day turnaround is a tall order, but with this unique structure from Tri-Arc Custom Solutions and the casters, bumpers, and crane from Conveyer & Caster-Equipment for Industry, it’s smooth sailing.

When customers look for unique solutions to move their unique products, they look to Conveyer & Caster- Equipment for Industry.

Enter your name and email address to subscribe to our newsletter featuring the latest in material handling and storage solutions (opt out at anytime).