Home » Technical Resources » Case Studies » Caster Case Studies » Glass Handling Casters – Upside Down is Right Side Up

Addis Glass of Cincinnati, Ohio is a large-scale glass fabricator. They specialize in custom cut and finished glass for residential and commercial installations, like shower enclosures and decorative glass windows.

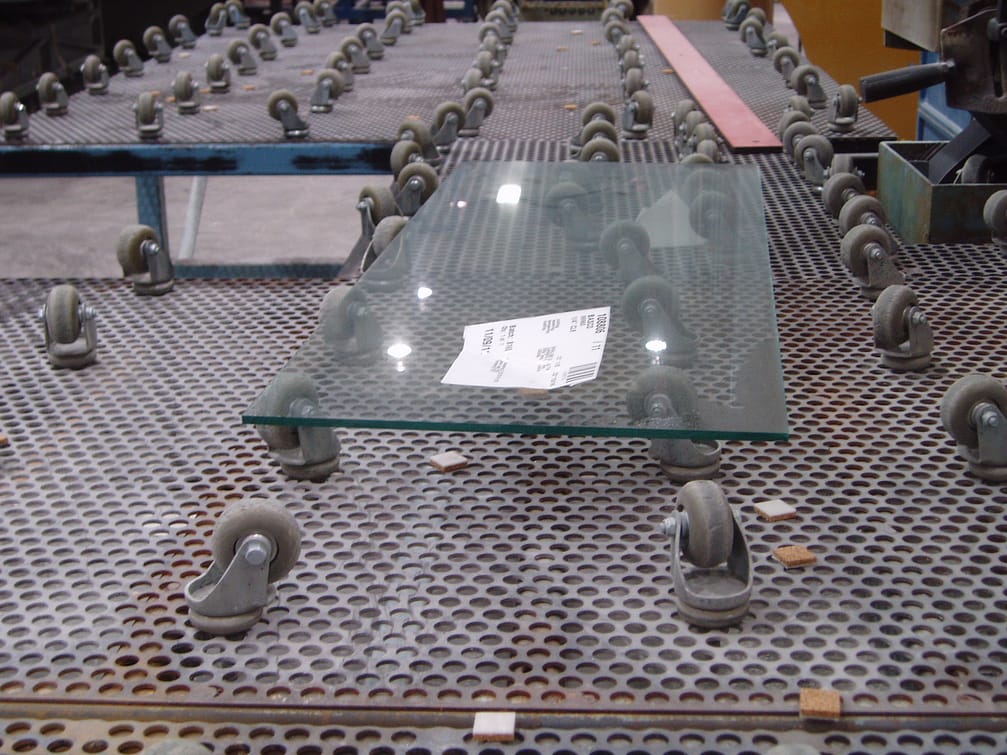

Addis Glass was having several issues with their glass buffing tables. Glass chips were cutting into and chunking out their existing glass handling casters; the work would have a rough ride across the table as a result. This rough ride would cause damage to the glass; which meant reworks, scrap, and longer production time.

To address this, Addis Glass first began by replacing the existing casters with the same style. Due to the design of the caster, producing a level surface is actually quite difficult. This less than level surface led to further damage to the work. Beyond that, they were expensive and provided the same result over time.

Addis Glass contacted Conveyer & Caster – Equipment for Industry, seeking a solution. Partnering with Shepherd Caster Corporation, Conveyer & Caster – Equipment for Industry, recommended a new style glass handling caster. Instead of using a bent metal arm and spherical ball, the new style caster features a more traditional caster design. Traditional except for being upside down. This glass handling caster features a sealed swivel section, sealed wheel bearing, and a soft but durable thermoplastic rubber tread. A level installation is always guaranteed, as there is only one installation height, instead of using an infinitely adjustable threaded stem. The new caster has provided Addis with fewer rejections and faster production time. According to Tom Vezdos of Addis Glass, “I wish I would have had these years ago. They move easier, are easier to install, competitively priced, and are all around better than the old casters.”

Have a problem like this? Give Conveyer & Caster – Equipment for Industry a call! We’ll keep your business rolling, upside down or right side up.

Enter your name and email address to subscribe to our newsletter featuring the latest in material handling and storage solutions (opt out at anytime).