In industrial settings where heavy lifting is a daily task, the risk of injury is a constant concern. Repetitive bending and lifting with twisting motions can wear down even the most in-shape and experienced workers. To address these challenges, ergonomic lifting aids and solutions are designed to take the strain off employees, making heavy lifting safer and more efficient. These tools help reduce the physical toll on workers while boosting productivity, ultimately creating a healthier and more productive workplace with significantly reduced costly workers’ compensation claims.

What Are Ergonomic Lifting Aids?

Ergonomic lifting aids are tools or equipment designed to reduce the strain on workers when handling heavy loads. These devices not only reduce the risk of injury but also improve efficiency by enabling workers to handle materials faster and with less fatigue. Ergonomically designed lifting solutions adapt to human capabilities, helping to maintain good posture and lessen the burden of repetitive movements.

Why Are Ergonomic Lifting Solutions Important?

1. Reducing Workplace Injuries:

Manual lifting, especially when done incorrectly or repeatedly with twisting motions, can lead to musculoskeletal disorders (MSDs), including sprains, strains, and back injuries. According to OSHA, musculoskeletal disorders are among the most frequently reported work-related injuries. Ergonomic lifting solutions mitigate this risk by taking on much of the physical strain.

2. Improving Productivity:

By reducing the physical toll on workers, ergonomic lifting solutions allow tasks to be performed faster and more efficiently. Workers can handle more materials with less effort, leading to greater output and fewer breaks due to fatigue or injury. As a byproduct, employees have also reported greater enjoyment and physical wellbeing of their work—increasing retention initiatives of employers.

3. Compliance with Regulations:

Many countries have safety standards that require employers to take measures to prevent injuries related to lifting and handling materials. Using ergonomic lifting aids helps companies comply with these regulations, reducing the likelihood of fines or penalties. In many cases, grants are even available to help companies invest in these safer material handling technologies and equipment.

Types of Industrial Ergonomic Lifting Aids

There is a wide range of ergonomic lifting aids available to suit your materials and processes, each designed for specific tasks and environments. Below are some of the most common solutions used in industrial settings:

Lift tables use hydraulic or pneumatic systems to raise and lower heavy loads. These tables can be adjusted to the height that is most comfortable for the worker, reducing the need for bending or reaching. Lift tables are widely used in assembly lines, packaging, and warehouse environments.

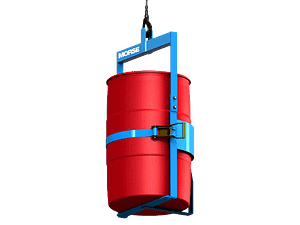

Hoists and cranes are ideal for lifting extremely heavy items, often in environments such as shipping yards, machine shops, and large warehouses. These devices can be electric, pneumatic, or manual, and allow workers to lift heavy loads with minimal effort.

Hoists and cranes are ideal for lifting extremely heavy items, often in environments such as shipping yards, machine shops, and large warehouses. These devices can be electric, pneumatic, or manual, and allow workers to lift heavy loads with minimal effort.

Vacuum lifters use suction to pick up items, making them perfect for handling awkward or delicate materials such as glass, sheet metal, or large sheets of wood. They reduce the need for workers to physically grasp heavy objects, significantly lowering the risk of hand or back injuries.

Vacuum lifters use suction to pick up items, making them perfect for handling awkward or delicate materials such as glass, sheet metal, or large sheets of wood. They reduce the need for workers to physically grasp heavy objects, significantly lowering the risk of hand or back injuries.

Carts with hydraulic lifts or scissor lifts provide mobility, allowing workers to move and lift heavy loads across a facility. These solutions are common in logistics and warehousing where material needs to be transported over longer distances.

Carts with hydraulic lifts or scissor lifts provide mobility, allowing workers to move and lift heavy loads across a facility. These solutions are common in logistics and warehousing where material needs to be transported over longer distances.

handles and grippers offer enhanced control, reducing the strain on the hands and wrists. These devices often use spring-loaded or cushioned designs to enhance the comfort and usability of standard lifting tools.

handles and grippers offer enhanced control, reducing the strain on the hands and wrists. These devices often use spring-loaded or cushioned designs to enhance the comfort and usability of standard lifting tools.

Custom Lifting Solutions for Specialized Tasks

While off-the-shelf lifting aids are widely available, some companies have specific material handling needs that require custom solutions. In such cases, partnering with a supplier that can design custom ergonomic lifting aids is key. From specialized vacuum lifters to fully automated systems, these solutions can be tailored to the workflow, materials, and ergonomic needs of the workers, ensuring both safety and efficiency.

How to Choose the Right Lifting Aid

Choosing the right ergonomic lifting solution depends on several factors:

- Type of load: What materials are being lifted? Are they heavy, delicate, awkwardly shaped, or require special handling?

- Frequency of lifting: Will the equipment be used constantly or intermittently? This affects whether a manual or powered solution might be more appropriate.

- Work Environment: Considerations like available space, the layout of the facility, and potential obstacles can influence the type of lifting aid that will be most effective.

- Worker capacity: Each lifting solution should be chosen with the worker’s capabilities in mind, ensuring it reduces strain without requiring additional effort or specialized skills to operate.

Conclusion

Investing in ergonomic lifting aids and solutions is a smart decision for any business that handles heavy or repetitive lifting tasks and can save the company money year-over-year with simple investments into lifting solutions. Not only do these solutions protect workers from injury, but they also boost productivity, compliance, and overall operational efficiency. From lift tables and hoists to vacuum lifters and customized equipment, there are ergonomic solutions available for nearly every industrial need.

At Conveyer & Caster, we specialize in providing ergonomic lifting solutions that prioritize worker safety while maximizing efficiency. Contact us today to explore how we can help you create a safer, more productive workplace with the right ergonomic lifting aids.